3D Print A New Liver

For all of you weekend warriors some exciting new open source 3D printing technology may well save your life one day. Researchers collaborating between Pennsylvania University and MIT have made significant strides in solving a huge problem in creating lab grown organs such as livers.

Scientists have been able to grow thin layers of cells for a long time now. These two dimensional sheets are easily supplied with nutrients, but methods to turn these two dimensional building blocks into something three dimensional has posed many difficulties.

Attempts at creating a three dimensional structure out of these sheets through layering have been unsuccessful because cells in the middle of the structure suffocate and die without access to these nutrients and with no way for waste to be carried away. Additionally, attempts at providing scaffolding between the sheets for which nutrient rich fluids can be pumped had caused the sheets to tear apart. This problem is being solved in an ingenious and inexpensive way using the open source 3D printer ‘RepRap’ and a little sugar.

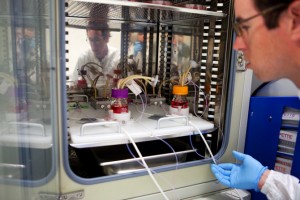

Using the 3D RepRap printer, researchers are printing fine structures made of glucose, sucrose, and dextran. The sugar structure is printed, and cells in a gel suspension are poured around the mold. Once the gel has set, the sugar is dissolved away leaving hollow channels throughout the cell dense gel in which nutrient solution can be pumped. Because sugar can be dissolved away and is not harmful to cells, it is an ideal medium to create a framework around which cells within the 3D structure can be supplied with nutrients.

Using this method, it has been shown that once healthy blood vessel cells are introduced, they begin to form capillaries on their own in the same way they would in the body. Due to the affordability of a RepRap printer vs. large commercial printers and the stability of the models it prints, it is feasible that soon cheap molds for vasculature in many different organs can be shipped around the world.

There are a few hurdles to traverse before this method becomes standard practice, however. The cell densities of the gels need to be brought up to that of a real organ. “The therapeutic window for human-liver therapy is estimated at one to 10 billion functional liver cells,” Sangeeta Bhatia, a researcher on the team said. “With this work, we’ve brought engineered liver tissues orders of magnitude closer to that goal, but at tens of millions of liver cells per gel we’ve still got a ways to go.” Scientists also need to figure out how to integrate the hollow channels into a hosts body effectively, so don’t go out and drink like it’s freshman year just yet!

Comments

Tags: 3d organ, 3d organ printing, 3D Printing, liver transplant, printed liver, printed organ, reprap

Trackback from your site.